Camera Communication Architecture

This page explains the OV20i's dual-tier communication design and how native industrial protocols work alongside Node-RED extensible communication capabilities.

Communication Architecture Overview

Two-Tier Communication Design

The OV20i implements a sophisticated communication architecture with two distinct layers:

Communication Tiers:

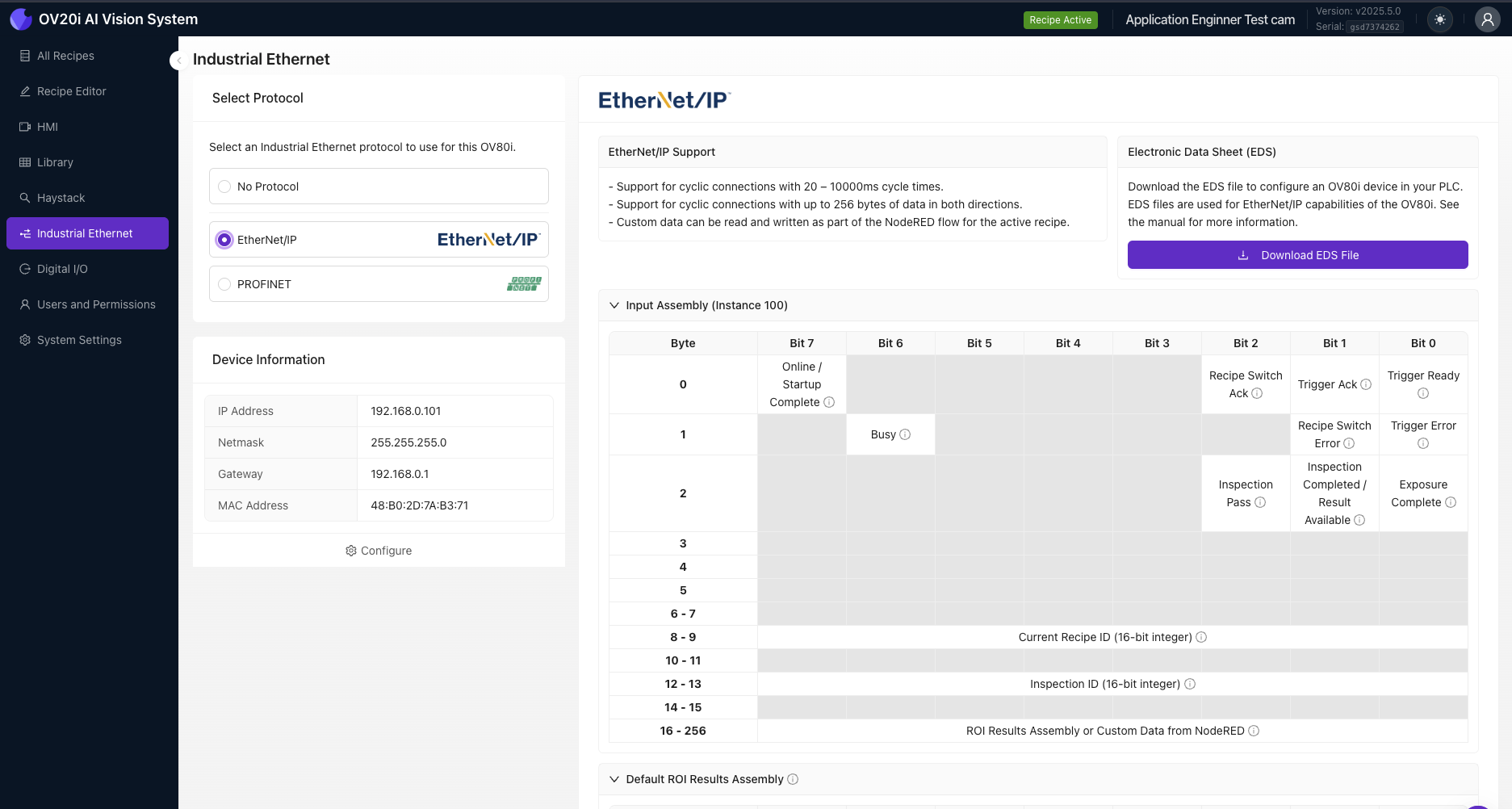

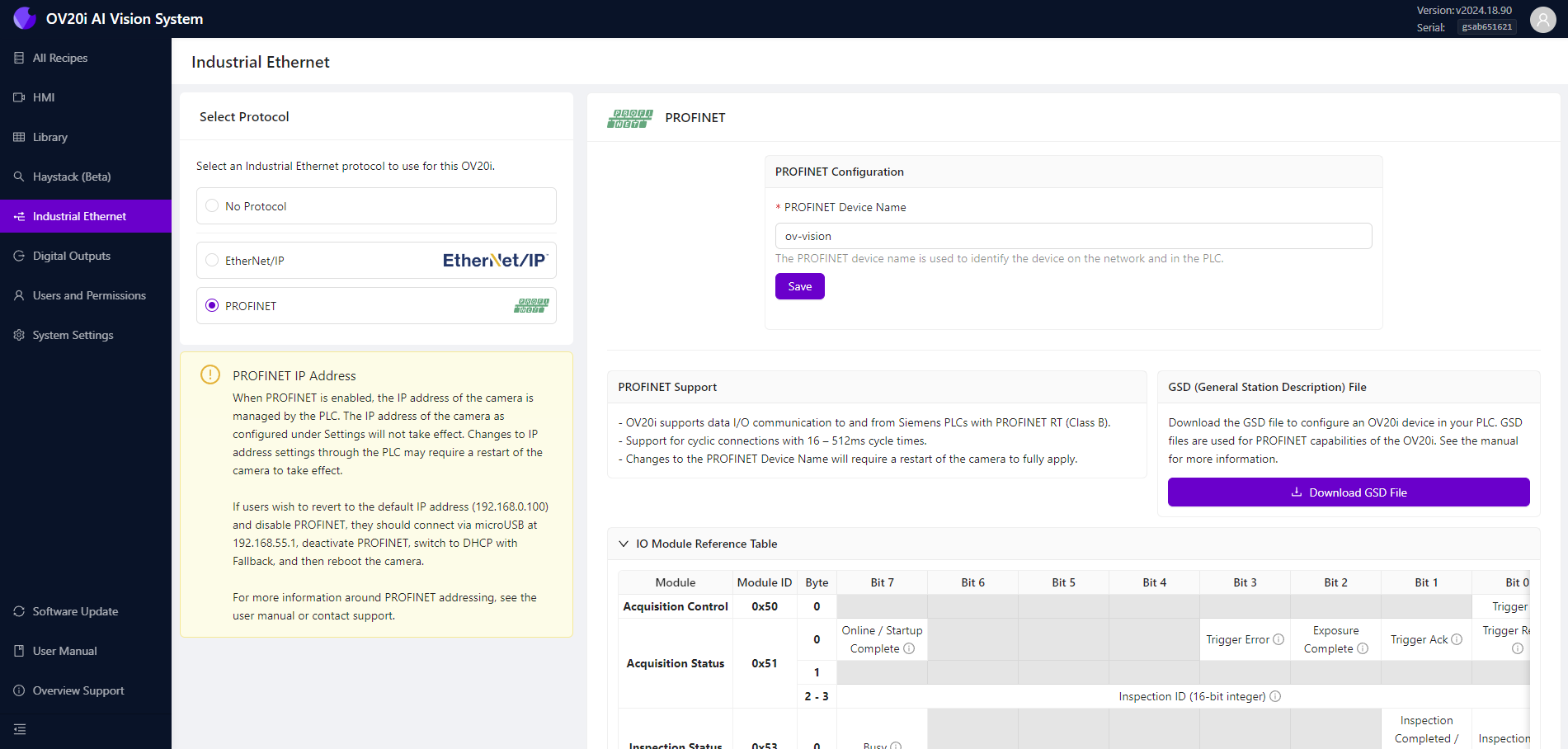

- Native Industrial Protocols - System-level built-in communication (Profinet, Ethernet/IP)

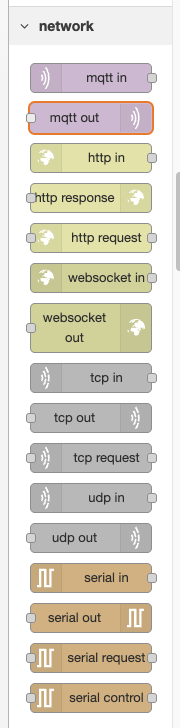

- Node-RED Extensible Protocols - Recipe-specific communication capabilities (MQTT, Modbus, TCP, HTTP)

Communication Scope and Control

System vs Recipe Level:

- System-level protocols apply globally across all recipes

- Recipe-level protocols are unique to each specific inspection workflow

- Configuration location determines communication scope and behavior

Native Industrial Communication

Built-in PLC Protocols

Camera System-Level Configuration:

- Profinet & Ethernet/IP - Only communication protocols configured at camera system level

- Direct Integration - No additional programming or Node-RED flows required

- Industrial Standards - Native support for major automation platforms (Siemens, Allen-Bradley, Mitsubishi, Omron)

- Bidirectional Data Exchange - Trigger commands, status feedback, recipe control, inspection results

Key Characteristics:

- Global Scope - Configuration affects all recipes

- System Settings - Managed through camera system configuration, not Node-RED

- Immediate Response - Direct hardware-level communication

- Industrial Reliability - Built for factory automation environments

References: Triggering Modes, System Settings Architecture

Node-RED Extensible Communication

Recipe-Level Protocol Flexibility

Node-RED Flow-Based Protocols:

- MQTT - IoT messaging and cloud integration via Node-RED flows

- Modbus - Industrial device communication through Node-RED nodes

- TCP - Custom protocol implementation for specialized systems

- HTTP - Bidirectional web service communication

Recipe-Specific Characteristics:

- Custom Logic - Each recipe defines its own communication workflows

- Protocol Selection - Choose appropriate protocols for specific inspection requirements

- Integration Flexibility - Connect to databases, cloud services, custom applications

- Data Processing - Transform and route inspection data as needed

References: Node-RED Basics, System Settings Architecture

HTTP Communication Duality

Inbound HTTP (Camera as Server):

- Open API Endpoints - External systems can trigger inspections remotely

- Recipe Management - Remote recipe switching and control via HTTP requests

- System Control - External applications can control camera functions

- Real-time Access - Immediate response to external HTTP requests

Outbound HTTP (Camera as Client):

- Node-RED HTTP Nodes - Camera initiates communication to external web services

- Custom Integration - Recipe-specific web service communication

- Data Publishing - Send inspection results to external systems and databases

- Third-party Integration - Connect to MES, ERP, and cloud platforms

Communication Flow Architecture

System-Level vs Recipe-Level Communication

Camera System Communication:

- Global Configuration - Profinet/Ethernet/IP settings apply to entire camera

- Network Foundation - IP addressing, subnet configuration affects all communication

- Built-in Protocol Support - No programming required for industrial integration

- Cross-Recipe Consistency - Same communication behavior regardless of active recipe

Recipe-Specific Communication:

- Unique Workflows - Node-RED flows are specific to each recipe

- Protocol Customization - Different recipes can use different communication methods

- Application Logic - Communication behavior tailored to inspection requirements

- Data Transformation - Recipe-specific data processing and routing

Communication Response Hierarchy

Immediate Response Tier:

- Digital I/O Signals - Hardware-level immediate response

- Native PLC Protocols - Direct industrial communication

Programmed Response Tier:

- Node-RED Flows - Custom logic and protocol handling

- Data Processing - Inspection result transformation and routing

External Integration Tier:

- HTTP Endpoints - Web service integration and external control

- Cloud Communication - MQTT and internet-based protocols

Integration Patterns and Strategies

Hybrid Communication Architectures

PLC + Node-RED Pattern:

- Native PLC for immediate triggers and status feedback

- Node-RED flows for data routing, logging, and advanced integration

- Best of both worlds - Industrial reliability with custom flexibility

HTTP Dual Direction Pattern:

- Inbound HTTP for external system control and triggers

- Outbound HTTP for data publishing and integration

- Bidirectional integration with web-based systems

Multi-Protocol Recipe Strategy:

- Different recipes using different communication protocols

- Application-specific communication methods

- Protocol selection based on integration requirements

Protocol Translation and Bridging

Node-RED as Communication Bridge:

- Protocol conversion between different industrial systems

- Data format transformation for system compatibility

- Communication routing between multiple external systems

- Integration hub for complex multi-system environments

Communication Architecture Benefits

Design Advantages

Industrial Reliability:

- Native protocols provide immediate, reliable industrial communication

- Proven standards ensure compatibility with existing automation systems

Flexibility and Extensibility:

- Node-RED platform enables custom communication solutions

- Recipe-specific communication adapts to application requirements

- Future-proof architecture supports new protocols and integrations

Operational Efficiency:

- Multiple communication paths provide redundancy and options

- Real-time capabilities support high-speed production requirements

- Custom data processing optimizes information flow for specific applications